Mean Time Between Failures

MTBF Prediction

After selecting the most reliable key components and optimizing the design and thermal characteristics, an MTBF can be determined.

Extreme Resilience

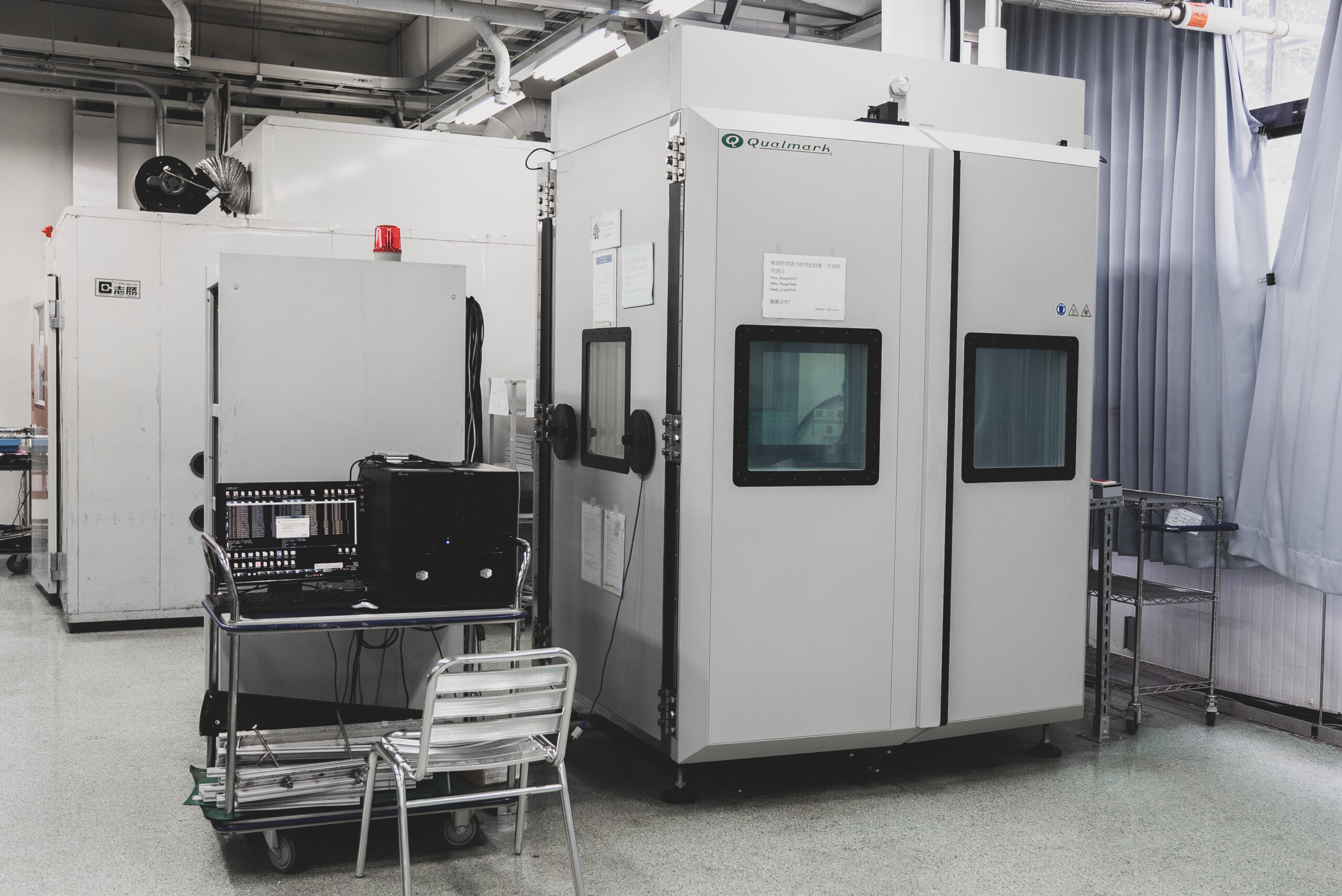

Environmental Test Capabilities

Temperature, humidity, thermal shock, and altitude. Shock, drop, bump, bounce, and earthquake. Sand/dust, rain, solar radiation, wind, salt spray, and gas corrosion. Acoustic, compression, ESD, ISTA transportation.

GR-63 Earthquake

Pallet Drop