For privacy reasons YouTube needs your permission to be loaded. For more details, please see our Privacy Policy.

Advanced Mechanical Design

Innovate, Elevate

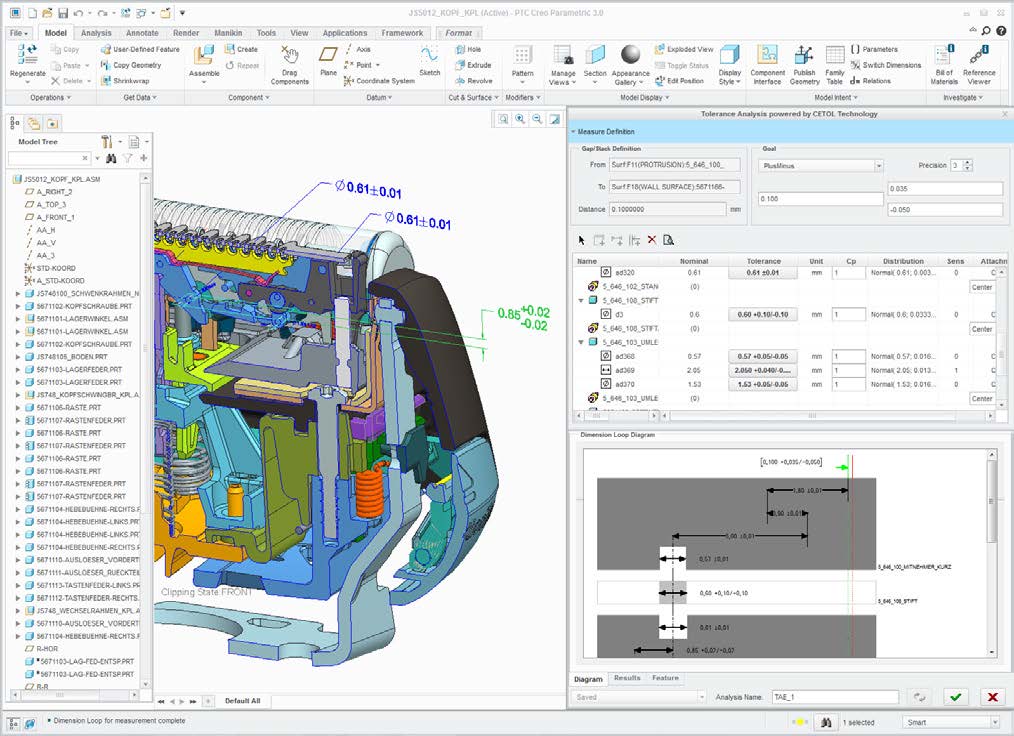

Accton continuously seeks to improve mechanical design elements in product development. The main focus is always to ensure product reliability, but efforts to shorten development cycles and reduce costs also play an important part.

Blueprints to Brilliance

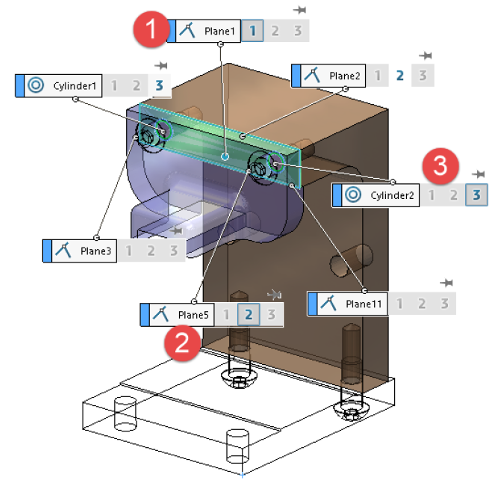

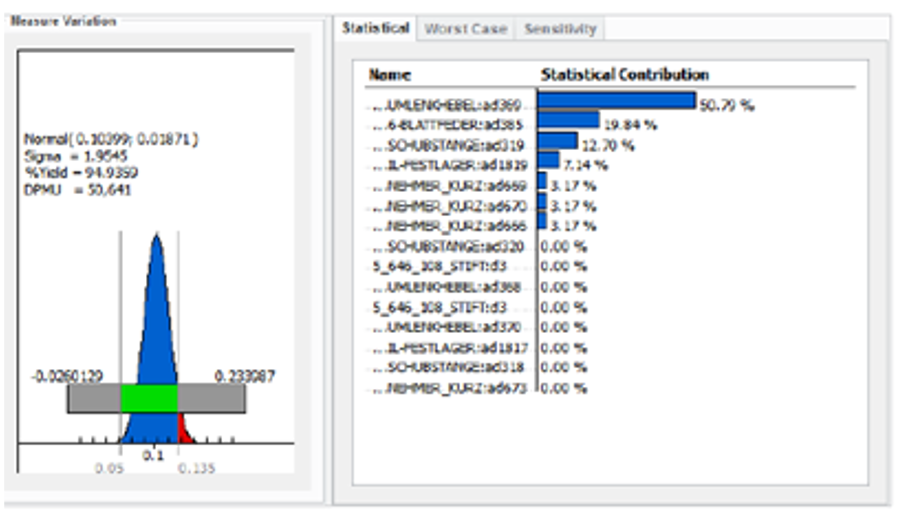

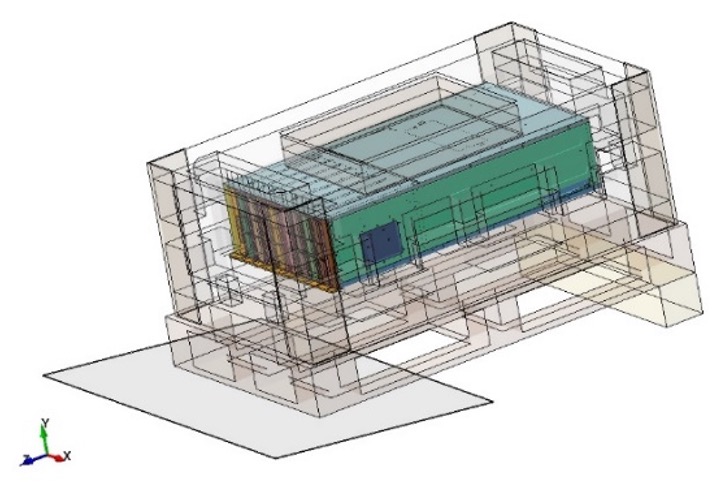

Structure Assessment & Risk Management

Before any PCB layout is undertaken, a cross-functional team decides on a balanced structure with a focus on device location, trace location, BGA and PCB contact force, and durability during the SMT process and shipping.