Responsible Supply Chain

Risk Assessment Process

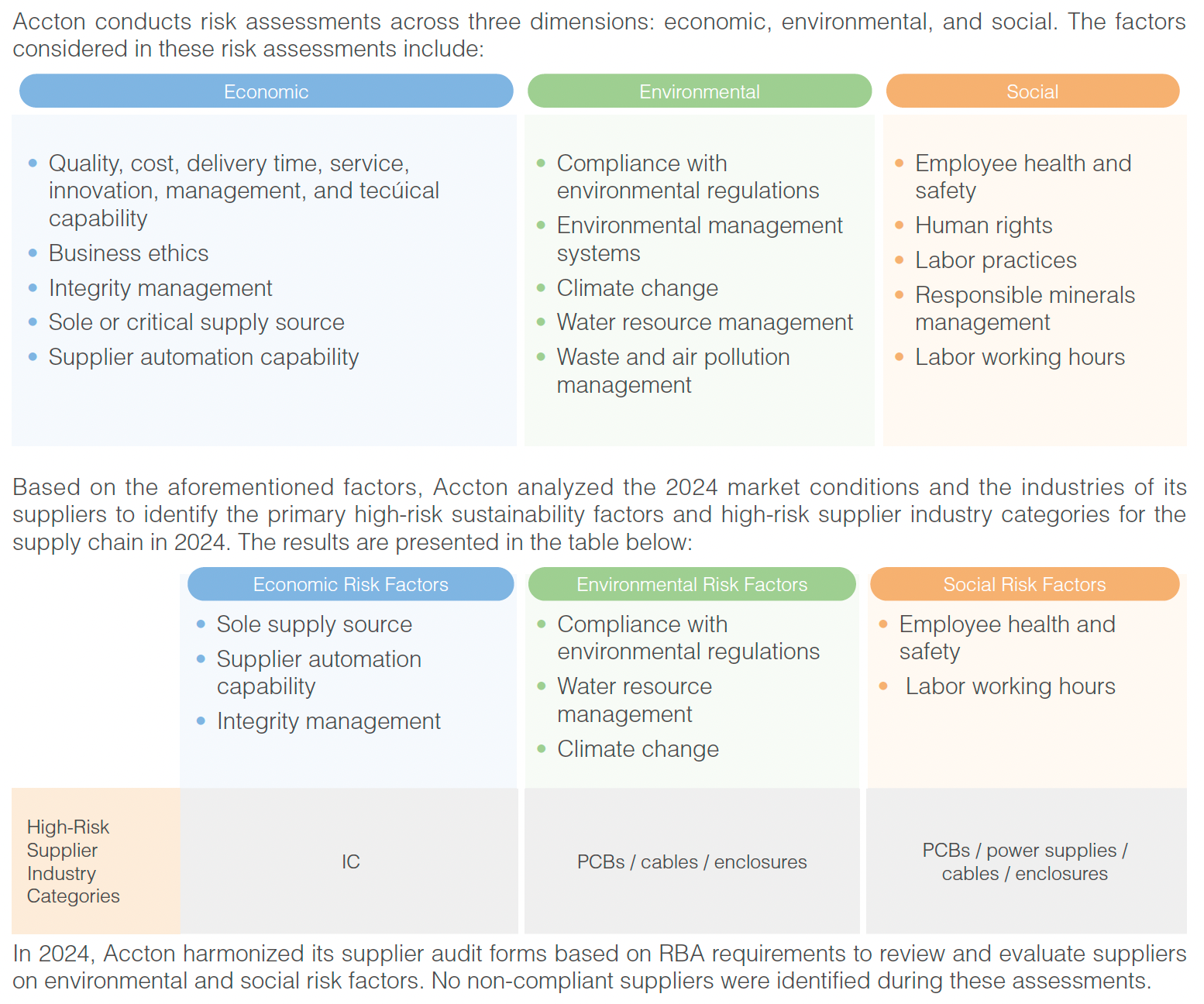

Accton regards supply chain risk management as a key component of its competitive advantage. Within the industry Accton operates, common risk factors can be briefly categorized across economic, environmental, and social dimensions based on industry characteristics.

Launch of the Zero Carbon Chain Project

On April 21, 2023, Accton held a supplier sharing conference for the Zero Carbon Chain Project, specifically choosing the day before Earth Day to emphasize the importance of this initiative. The theme of the conference was “Zero Carbon Chain,” aimed at building consensus with supplier partners to jointly develop ESG sustainability and carbon reduction action plans. The event underscored the significance of future carbon reduction and ESG sustainability actions in Accton’s overall supply chain management.

Environmental Management

Accton Group is committed to implementing Hazardous Substance Free (HSF) management. Our Accton Zhubei AI Park, Hsinchu Science Park, Zhunan Plant in Taiwan and Vietnam Accton have all continuously passed the annual certification of the IECQ QC 080000 system. All products comply with international environmental regulations (e.g., EU RoHS, REACH directives), aiming to achieve the goal of using environmentally friendly materials through green supply chain management. This allows Accton to produce and provide customers with low-pollution green products that reduce associated harm to humans and the environment.

Conflict Minerals

Respecting international human rights and corporate social responsibility, Accton Group avoids using minerals from areas affected by armed conflict and human rights abuses. Through regular due diligence as part of the Responsible Minerals Initiative (RMI), suppliers are required to source raw materials that do not originate from Conflict-Affected and High- Risk Areas (CAHRAs). This is to prevent indirect human rights violations and ensure compliance with national and international laws.