The Cornerstone of Operational Resilience: From Crisis Awareness to Collective Action

ESG Spotlight / Governance 👨🏫 / Business Continuity Management Center / October 29th, 2025

Safety Management: The Core Foundation of Sustainable Operations and Corporate Governance

For Accton Technology, plant safety management is not merely a matter of regulatory compliance but a cornerstone for ensuring sustainable operations.

Our disaster mitigation goals are clear: protect lives, safeguard assets, and maintain business continuity. Any unexpected incident, whether a fire, chemical spill, or natural disaster, can trigger a chain reaction. Minor cases may endanger employee health and safety, while severe ones can result in asset losses, supply chain disruptions, or even damage to customer trust and corporate reputation.

That is why proactively identifying, addressing, and managing potential operational risks is Accton’s top priority under its corporate governance framework.

We adhere to a safety strategy that emphasizes both prevention and preparedness, believing that “prevention is better than cure” is the most fundamental principle in facing any disaster. The foundation of prevention lies in every employee’s internalized sense of safety.

Accton regards emergency response drills as part of a continuous journey in building a safety-oriented culture, not as an annual formality.

Through regular and practical drills, we transform abstract crisis awareness into concrete response capability. This company-wide commitment to safety demonstrates Accton’s determination to protect lives and assets and embodies the highest standard of operational resilience in corporate governance.

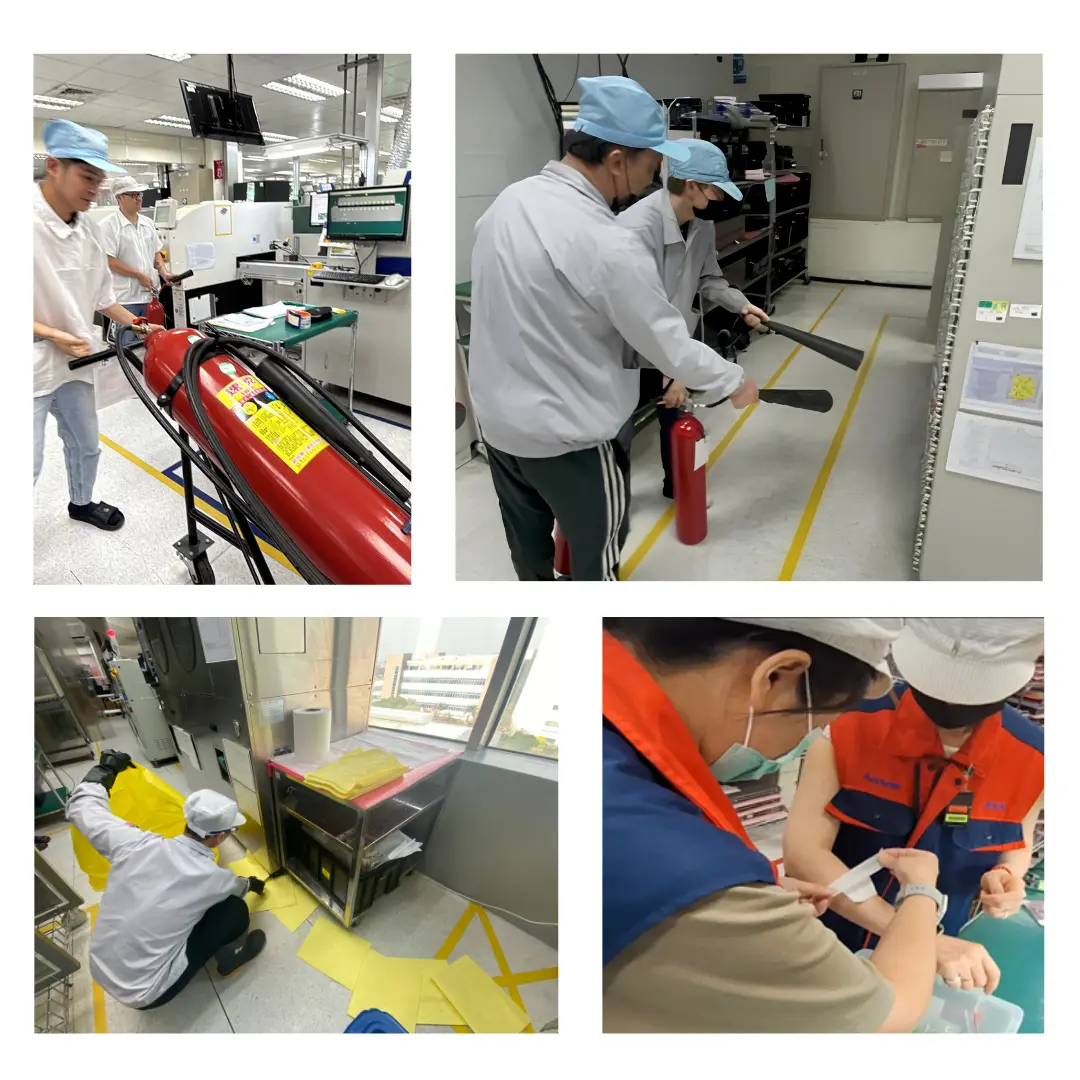

Firefighting Drill at the Minghu Fire Training Base

Learning from Adverse Situations: Strengthening Safety Culture and Fulfilling Collective Responsibility

To deepen employees’ safety awareness, Accton designs its drills with a focus on “starting from everyday actions.”

We select realistic yet challenging scenarios for training, such as conducting drills during holiday nights when manpower is limited. This approach breaks the misconception that every drill must go perfectly, allowing employees to learn from mistakes and strengthen their adaptability.

Each drill scenario is designed based on fire risk assessments conducted by on-site supervisors, who determine priorities according to risk levels.

The company conducts monthly mini-drills that emphasize the first three minutes of emergency response after a fire is detected. These sessions simulate equipment malfunctions, small-scale fires, and first-aid situations, helping employees become familiar with the sequence of actions, “alert, power off, extinguish”, as well as evacuation procedures.

Drill coverage spans from basement to rooftop, and from indoor to outdoor areas, involving not only production lines and facility teams but also warehouses, cafeterias, and kitchens. This ensures that every area of the site is equipped with proper response capabilities, forming a seamless safety defense network across the campus.

More importantly, each drill reinforces Accton’s core belief: “Safety is a shared responsibility for every employee.”

When emergency response becomes instinctive and fire safety awareness becomes part of our culture, we not only protect our people but also enhance cross-departmental coordination and mutual support.

This safety culture rooted in daily practice serves as the best indicator of a company’s risk management maturity, achieving our disaster mitigation goals of protecting lives, safeguarding assets, and ensuring business continuity.

Responding to Compound Disasters: A Commitment to ESG Practice and Continuous Improvement

In an era of climate change and increasing risk complexity, the threats facing industrial facilities are no longer singular. An earthquake, for example, may simultaneously cause power outages, equipment damage, and chemical leaks—creating a high-risk scenario of compound disasters.

At Accton, we learn from real-world incidents across the industry to assess and strengthen our own disaster mitigation capabilities.

Our emergency drills continue to evolve, expanding from single fire-escape exercises to multi-departmental coordination and decision-making simulations, and even joint drills with neighboring companies within the same building. These exercises test not only our response procedures but also the effectiveness of our command systems and resource allocation.

Since 2024, Accton Technology has conducted over 50 emergency response drills across its Taiwan campuses, covering daytime, nighttime, and holiday scenarios, with more than 650 total participants.

Through repeated testing, our employees’ independent disaster prevention and response capabilities have significantly improved.

After every drill, we implement the PDCA (Plan-Do-Check-Act) cycle. Participants conduct After Action Reviews (AAR) to document strengths, weaknesses, equipment gaps, and skill needs. These insights are then integrated into our annual capital expenditure and training plans.

We embrace the imperfections in every drill, drawing on collective intelligence to transform lessons learned into momentum for continuous ESG improvement. This commitment to transparency and ongoing enhancement drives Accton’s progress in safety management.

Because we believe that by sharing knowledge and learning together, we can protect more people.

We are Accton.

Achievements

| From 2024 to Q2 2025, Accton conducted over 50 emergency response team drills across its four campuses, Hsinchu Science Park, Hsinchu Plant II, Zhunan Plant, and Zhubei AI Park, with a total participation of more than 650 employees. |

|---|

Related Page(s)

The Cornerstone of Operational Resilience: From Crisis Awareness to Collective Action

summer2025-10-29T09:31:35+08:00October 29th, 2025|

From Art to Action: Accton’s Commitment to Marine Conservation

summer2025-10-01T13:31:53+08:00September 30th, 2025|